Diesel Engine

Bi-Fuel

Conversion

Bi-fuel Diesel Engine Conversion

If you want to cut down on diesel fuel use for diesel engines in power generation and the costs that come with it, you may benefit from an OptiBlend® bi-fuel diesel engine conversion solution.

The OptiBlend® conversion kit uses custom equipment to introduce natural gas into the engine’s intake air stream, providing additional energy to your engine while requiring less diesel fuel to operate at full power.

OptiBlend® Bi-fuel Conversion Kit

The OptiBlend® bi-fuel diesel engine conversion kit uses several key components to retrofit diesel power generators and convert them into bi-fuel generators.

With the help of our solution, you can experience the following key benefits:

- Cost Savings — You’ll be able to cut down on the costs of power generation by supplementing diesel fuel with various types of energy-efficient natural gases, including wellhead gas, methane, and hydrogen. These cheap fuel sources can be used to reduce the use of expensive diesel fuel.

- Extended Runtime — Another advantage of bi-fuel conversion is the ability to use less diesel fuel when combined with natural gas, helping ensure your diesel supply lasts longer. This can help in situations where diesel fuel may be difficult or impossible to source and have delivered.

- Reduced Emissions — Reduce the levels of CO2, NOx, SOx, particulate matter, and other harmful emissions from your power generator with a bi-fuel solution, increasing your operation’s sustainability and decreasing its environmental impact.

OptiBlend® has developed a reliable solution to convert diesel power generators and other constant-speed diesel engines into bi-fuel systems that combine the reliability of diesel technology with the efficiency of natural gas.

Diesel Power Generators

The OptiBlend® conversion kit is compatible with many types of power generators from the industry’s leading brands, including Cummins, Caterpillar, MTU, Kohler, John Deere, and Generac. Specifically, we can provide solutions for constant-speed power generators for use in stationary applications, excluding variable-speed diesel engines such as those used in heavy equipment and transport.

You can use our bi-fuel conversions for power generation in many types of applications, including:

Remote Sites

If you need reliable power generation in a remote site, an OptiBlend® bi-fuel conversion kit will accommodate this need. Remote sites such as temporary medical sites, along with other facilities in search and rescue operations, need continuous and long-lasting power. Bi-fuel generators can meet this requirement with energy-efficient power that makes the most of available diesel fuel.

Emergency Power

In the event of a surge or other issue causing power outages, many homes and businesses will require emergency power. Often, people and companies will require power for long periods while working with limited diesel supplies. Bi-fuel diesel engine conversion systems will extend generators’ runtimes and keep operations cost-effective when facilities require emergency power.

Disaster Relief

Natural disasters like hurricanes may require the deployment of temporary shelters and other facilities relying on continuous power. Bi-fuel generators assist with disaster relief efforts by providing dependable, long-lasting power when it’s most important.

OptiBlend®

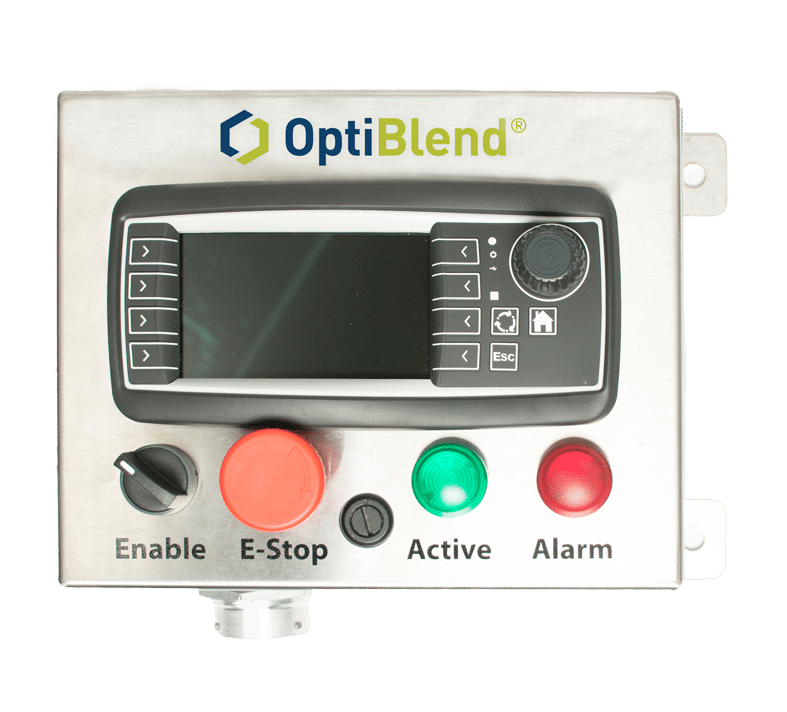

Our conversion kits include gas trains, air gas mixers (AGMs), fuel control valves (FCVs), and control panels. No internal modification to the engine is required to retrofit any existing or newly-purchased power generator to run on bi-fuel.

Our solution works with most 200kW to 2000kW applications requiring dependable power generation. The expected results will include reduced emissions, cut operational costs, and extended runtimes for power generators.

Our installation services and training process help effectively convert power generators and ensure our customers get the best results from them. To calculate the benefits and get started on an installation for your diesel engine, contact our engineering team today.

Bi-Fuel Diesel Engine Conversion - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.

Bi-Fuel Diesel Engine Conversion - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.  Bi Fuel System Components - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.

Bi Fuel System Components - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.  OptiBlend : Bi-Fuel Engine - OptiBlend bi-fuel technology optimally retrofits 200-2000 kVA, doubling runtime while significantly reducing operations cost. ROI is often within the first year of operation.

OptiBlend : Bi-Fuel Engine - OptiBlend bi-fuel technology optimally retrofits 200-2000 kVA, doubling runtime while significantly reducing operations cost. ROI is often within the first year of operation.

Dual Fuel : Diesel – Natural Gas Conversion Kits - Lower fuel cost. Improved NoX…

Dual Fuel : Diesel – Natural Gas Conversion Kits - Lower fuel cost. Improved NoX…  Optiblend Bi-Fuel Diesel Engine Conversion - Adding a secondary gaseous fuel…

Optiblend Bi-Fuel Diesel Engine Conversion - Adding a secondary gaseous fuel…  Bi-Fuel Diesel Engine Dealers - OptiBlend bi-fuel technology works with…

Bi-Fuel Diesel Engine Dealers - OptiBlend bi-fuel technology works with…  Diesel Equipment : Bi-Fuel Conversion - An OptiBlend dual fuel retrofit…

Diesel Equipment : Bi-Fuel Conversion - An OptiBlend dual fuel retrofit…  Bi-Fuel Diesel Natural Gas Power Generator Conversion - OptiBlend dual fuel retrofit systems…

Bi-Fuel Diesel Natural Gas Power Generator Conversion - OptiBlend dual fuel retrofit systems…  Bi Fuel Gas Train - OptiBlend dual fuel gas train…

Bi Fuel Gas Train - OptiBlend dual fuel gas train…  Bi Fuel Air Gas Mixer Valve (AGM) - OptiBlend dual fuel conversion uses…

Bi Fuel Air Gas Mixer Valve (AGM) - OptiBlend dual fuel conversion uses…  Bi-Fuel Control Valve - OptiBlend dual fuel conversion kits…

Bi-Fuel Control Valve - OptiBlend dual fuel conversion kits…  Bi-Fuel Control Panel - OptiBlend dual fuel conversion kits…

Bi-Fuel Control Panel - OptiBlend dual fuel conversion kits…