Two Fuels Are Better Than One™

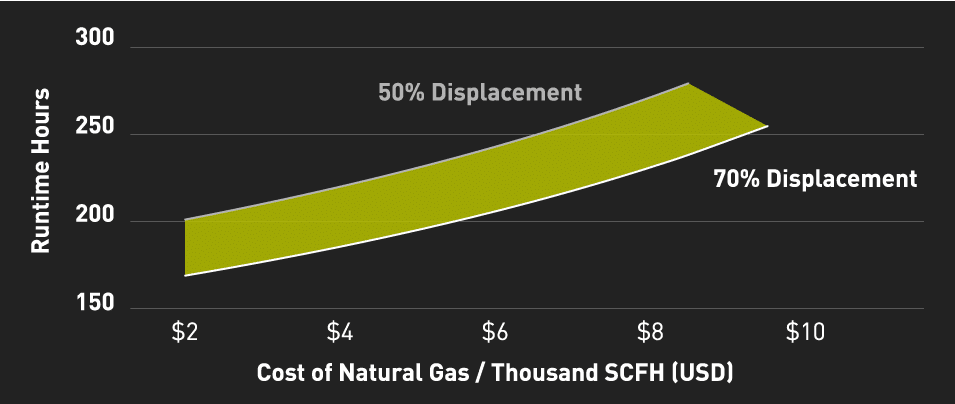

Extended Runtime

Ongoing Savings

OptiBlend® technology allows your conventional diesel engine to use natural gas as its primary fuel without modifying the engine or the diesel fuel system. The result? Lower fuel costs, improved NOx and CO2 emissions, and increased runtime.

Starting from left – Fuel Control Valve (FCV) & Air-Gas Mixer (AGM)

Achieve ROI in 250 runtime hours or less.

See why OptiBlend® is revolutionizing the Dual Fuel System industry.

Ready for any industry.

Clean, reliable, economical. OptiBlend® can handle it all.

OptiBlend Dual Fuel for Power Generators

OptiBlend® dual fuel diesel power generator conversion kits include a gas train, dual fuel mixer valve and control panel. These kits are installed and commissioned by our technicians. Dual fuel generators reduce costs and CO2 emissions while extending runtime.

OptiBlend Bi-Fuel for Diesel Equipment

OptiBlend® dual fuel for diesel equipment is ideal for constant speed power applications. Extend the runtime of your bi-fuel power generator, lower fuel costs and reduce CO2 emissions. Learn how a bi-fuel mixer valve, gas train & control panel are installed on bi-fuel generators.

OptiBlend Bi-Fuel for Diesel Engines

OptiBlend® bi-fuel for diesel engines are designed for constant speed power applications of 200kW – 2000kW. A bi-fuel diesel engine retrofit offers significant fuel savings with an ROI that typically happens in months. Not certain about a dual fuel engine vs. a bi-fuel engine? Read more here…

OptiBlend Dual Fuel by Industry

OptiBlend® dual fuel for diesel engines technology has been installed in hospitals, medical facilities, assisted living centers, data centers, remote oil & gas pumping/drilling operations. First responders use our dual fuel system for disaster response, response and recovery to extend runtime and keep the power on.