Dual Fuel Conversion Kit : Training

Dual Fuel Conversion Kit: Training & Support

Training

A certified OptiBlend® installation technician will review the startup, shutdown, and maintenance of the dual-fuel system on-site with your designated personnel. The technician will capture photos and notes of the specific installation along with operational minimum and maximum ranges set and recorded during the system commissioning. This information is provided to you as well as maintained by OptiBlend® technical support for future .

Customers are welcome to install OptiBlend® systems themselves and then have a certified OptiBlend® technician inspect the installation and commission the engine on dual fuel. Any engines which are not commissioned by a Certified OptiBlend® technician are not covered under warranty. Eden Innovations LLC offers OptiBlend® Technician Training. The training covers theory of operation, materials, installation, commissioning, and troubleshooting.

Diagnostics

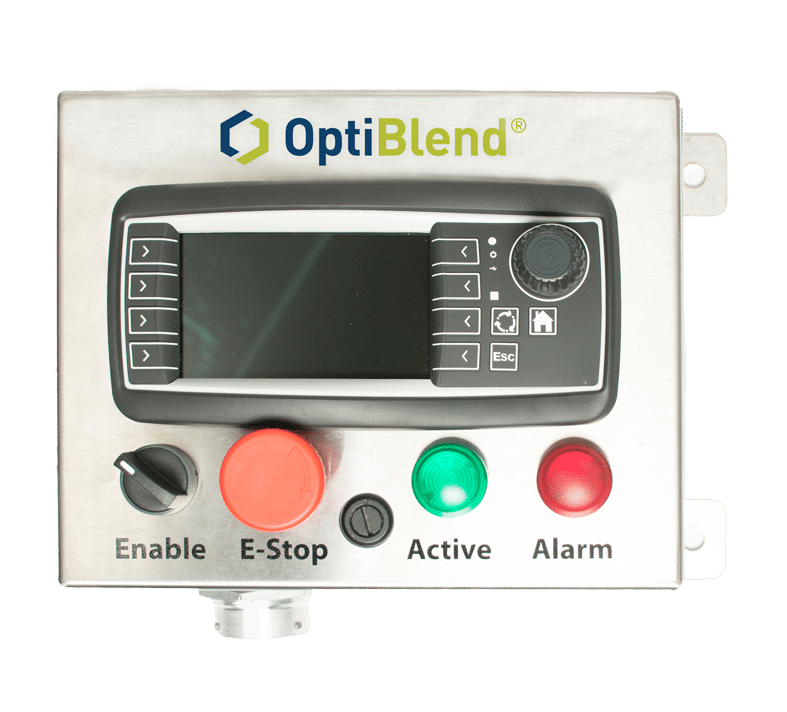

Your technician will review the various alarms and possible solutions with your personnel to ensure your team can troubleshoot issues. The OptiBlend system provides information regarding dual fuel performance, self-diagnostics, and some engine parameters. A comprehensive troubleshooting guide is included in the operation manual. The OptiBlend HMI displays alarms for easy visibility. The HMI also records event history and data in an easy-to-use USB.

Service

Service intervals for the diesel generator remain unchanged after the OptiBlend® conversion. The dual fuel system requires very little service. The gas filter element should be changed a minimum of once per year or anytime the pressure differential has increased 100% compared to a new filter or when the pressure differential exceeds 0.15psig (10mbar). The zero-pressure regulator (ZPR) requires inspection annually. If there is visible wear on the unit a rebuild kit can be obtained from Eden Innovations LLC.

Support

Technical phone support is available Monday through Friday 8AM – 5PM MT. Emergency support is available 365 days of the year. Onsite service technicians can be scheduled to replace system parts, configure and/or tune systems that are not operating optimally or address issues related to an OptiBlend® system installation.

Bi-Fuel Diesel Engine Conversion - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.

Bi-Fuel Diesel Engine Conversion - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.  Bi Fuel System Components - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.

Bi Fuel System Components - OptiBlend bi-fuel retrofit system uses a gas train & electronic software device to constantly monitor engine performance & gaseous flow for safe & efficient operation.  OptiBlend : Bi-Fuel Engine - OptiBlend bi-fuel technology optimally retrofits 200-2000 kVA, doubling runtime while significantly reducing operations cost. ROI is often within the first year of operation.

OptiBlend : Bi-Fuel Engine - OptiBlend bi-fuel technology optimally retrofits 200-2000 kVA, doubling runtime while significantly reducing operations cost. ROI is often within the first year of operation.

Optiblend Bi-Fuel Diesel Engine Conversion - Adding a secondary gaseous fuel…

Optiblend Bi-Fuel Diesel Engine Conversion - Adding a secondary gaseous fuel…  Diesel Equipment : Bi-Fuel Conversion - An OptiBlend dual fuel retrofit…

Diesel Equipment : Bi-Fuel Conversion - An OptiBlend dual fuel retrofit…  Bi-Fuel Diesel Engine Conversion - OptiBlend's dual fuel diesel engine…

Bi-Fuel Diesel Engine Conversion - OptiBlend's dual fuel diesel engine…  Bi-Fuel Diesel Natural Gas Power Generator Conversion - OptiBlend dual fuel retrofit systems…

Bi-Fuel Diesel Natural Gas Power Generator Conversion - OptiBlend dual fuel retrofit systems…  Bi Fuel Gas Train - OptiBlend dual fuel gas train…

Bi Fuel Gas Train - OptiBlend dual fuel gas train…  Bi Fuel Air Gas Mixer Valve (AGM) - OptiBlend dual fuel conversion uses…

Bi Fuel Air Gas Mixer Valve (AGM) - OptiBlend dual fuel conversion uses…  Bi-Fuel Control Valve - OptiBlend dual fuel conversion kits…

Bi-Fuel Control Valve - OptiBlend dual fuel conversion kits…  Bi-Fuel Control Panel - OptiBlend dual fuel conversion kits…

Bi-Fuel Control Panel - OptiBlend dual fuel conversion kits…  Bi Fuel Engines - Bi-fuel vs. dual fuel, what…

Bi Fuel Engines - Bi-fuel vs. dual fuel, what…