Dual Fuel Extended Runtime & Diesel Fuel Displacement

Diesel Fuel Displacement

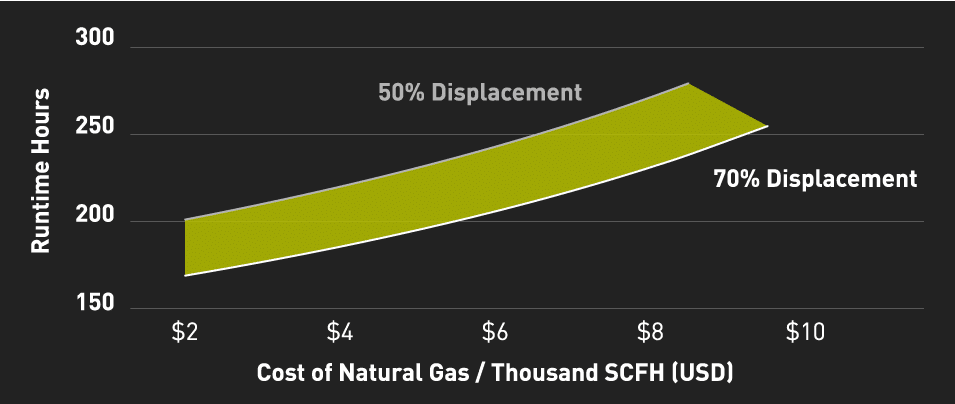

Diesel fuel compression ignition engines retrofitted with the dual fuel kit use natural gas as the primary fuel. The advantages are both economic and environmental. Typically, 50% to 70% of diesel fuel normally used can be safely displaced with natural gas. The OptiBlend™ system is designed to allow for fuel switching during full or partial load conditions without interruption of engine speed or power. Displacement of diesel should never exceed 70%. Typical is 50% to 60%. It is not recommended to exceed 50% displacement at 100% load.

Contact Us

OptiBlend® in Social Media

Related Videos

Popular Articles

Ready for Any Industry.

Learn why OptiBlend® is the answer to lower fuel costs, improve emissions, and increase runtime in any industry.